IEC standard compliant series

Clean wear made with IEC standard compliant materials used in the EPA area of clean environments

The IEC standard is an international standard for protecting electronic devices from electrostatic phenomena. (for a detailed explanation see " About the IEC standard " below)

In recent years, the trend domestically has been to manufacturing processes that conform to the IEC standard when developing products that combat static electricity.

Our company understood the need to conform and developed clean wear using materials (GK330G, GK340G) that were among the first to be formally certified as IEC compliant.

About the IEC standard

The IEC, properly known as the International Electrotechnical Commission, is constituted of representative standardization organizations from each country, and is responsible for creating international standards in the fields of electrical and electronic technology.

Clothing must conform to the conditions set out below.

Requirements for clothing

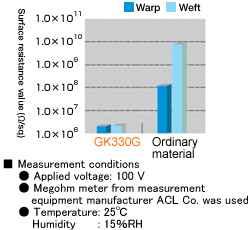

Every part of the clothing must be electrically continuous and the surface characteristics must have a resistance of Rp≦1×1012〔Ω〕between 2 points. When resistance between points is (Rp)>1×1010〔Ω〕regulations stipulate that the charge decay (Max.1,000V) must go from start to 10% in fewer than 2 seconds.

Requirements for shoes

Regulations stipulate that the resistance characteristic must be 1×105≦Rg1×108〔Ω〕when worn by an operator.

Reverse core-in-sheath Belltron is used to give this material ultra-antistatic properties. Belltron a fiber with outstanding static-eliminating ability, is not introduced into the core of the fiber, but is used instead on the fabric’s surface, which notably strengthens its anti-static properties. In addition, the use of a long-lasting anti-static process prevents the emission of static electricity. Highly effective anti-static threads are woven in a 5mm grid, making it extremely durable.

- Cross-section electron micrograph

- Comparison of surface resistance

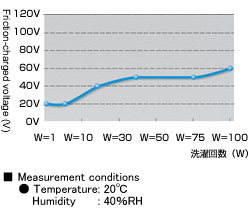

- Changes in washing durability

- Washing durability test data

![[C.U.O.S]カスタマイズオプションシステム](../user_data/packages/default/img/banner/cuos.jpg)